Intellijoint Surgical is proud to announce a new, optional feature to the Intellijoint KNEE system. It helps provide quantitative measurements of femoral and tibial rotational alignment.

Originally released back in 2020, Intellijoint KNEE is the second application following the company’s flagship product, Intellijoint HIP. The Intellijoint team has continued to innovate and expand the system’s feature set since and well over 1,500 surgeries have been completed with the Intellijoint KNEE navigation system. This number is growing daily!

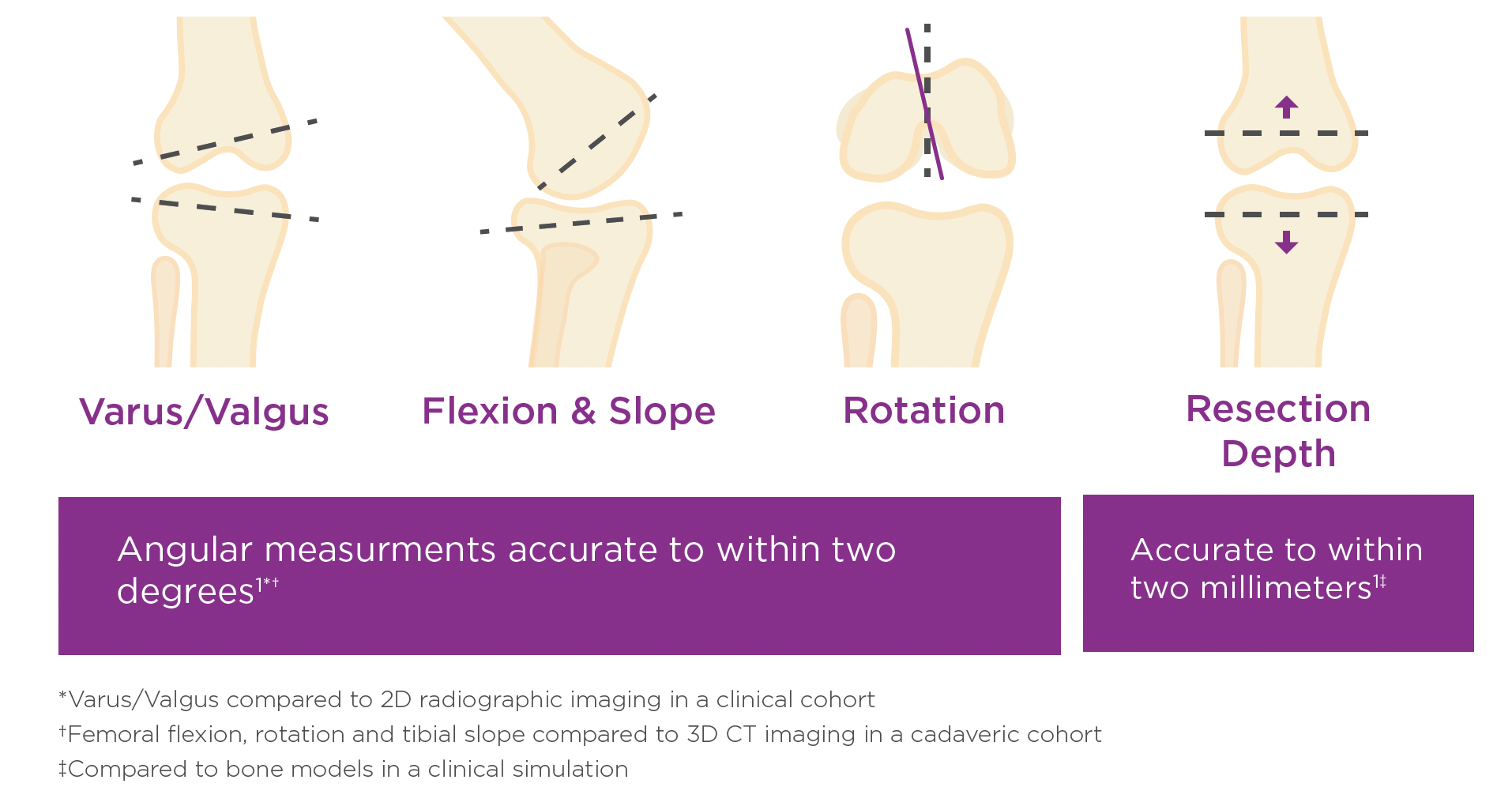

Intellijoint KNEE is a fast and easy-to-use surgeon-controlled navigation system. It provides real-time measurements of varus/valgus, flexion, slope, resection depth, and most recently added, rotation, to give confidence in femoral and tibial implant placement during Total Knee Arthroplasty (TKA).

Femoral rotation measurements can be displayed relative to 3 different reference axes:

- the Whiteside’s Line

- the Transepicondylar Axis (TEA) and the

- Posterior Condylar Axis (PCA).

Tibial rotation measurements are displayed relative to the Anterior-Posterior (AP) axis. The rotation feature is a tool that helps surgeons gain further insight into their own practice and achieve consistency in their results.

First cases with the rotational feature were completed at the Hospital for Joint Disease in New York City, NY and at Houston Methodist Hospital Outpatient Centre in Houston, TX. The rotation feature was also showcased at the AAKHS 2021 tradeshow.

Product Development Manager, Samantha McCabe, describes the features considered when developing Intellijoint KNEE.

SIMPLICITY EQUALS SPEED

While designing the product, we consulted with a number of key opinion leaders. They were adamant that they wanted a product that did not add time to their case - a sentiment we heard from many orthopaedic surgeons. Increasing case time delays not only irritates nursing staff, it reduces the number of procedures performed in a day and it increases the overall procedure cost (along with patient infection risk and time under anesthesia). To minimize time-add, we focused on two areas: system setup and intraoperative time.

System setup

Through many conversations and case observations, we learned that nurses and technicians have a lot of complex tools to set up at the beginning of a total knee arthroplasty (TKA). To reduce the time burden on them, the Intellijoint KNEE system requires only three (3) assembly steps. These steps eliminate the need for traditional intramedullary and extramedullary jig set-up and do not involve calibration. This results in a time-neutral and minimally disruptive set-up experience.

Operative Time

To reduce intraoperative time-add, we designed a streamlined feature set that provides only relevant information to surgeons. The system provides the proximal tibial and distal femoral cut angles and resections. By focusing on these features, we give surgeons confidence in their implant alignment without adding unnecessary time to the procedure. Additionally, we made the registration process as simple as possible.

FLEXIBILITY MAKES SWITCHING EASY

All of our consulting surgeons have a slightly different workflow and philosophy about TKA. We made the system quite flexible to accommodate all workflows and preferences. Users can place the single pin bone reference in a variety of locations within their main incision, they can choose to use the provided system cutting guide, or they can use their standard implant vendor cutting guide. With these design decisions, there is no need for a user to alter their approach or workflow to use the system!

Nothing is ever perfect on the first try. For us, getting to the current feature set took a few iterations. The first prototypes we showed surgeons and used in cadaver labs had more features and hardware to enable more options. As a designer, it is hard to eliminate a feature or hardware component that you have spent time designing, building, refining and testing. However, Intellijoint KNEE is proving that the simplest solution is usually the best solution.

The research and development (R&D) team at Intellijoint is passionate about making products that bring value to surgeons and patients. We are all proud of Intellijoint KNEE and look forward to seeing it used more frequently by orthopaedic surgeons around the world.

We believe in continuous improvement of our products. If you have any feedback, we would love to hear from you!

Intellijoint KNEE is available now! Please contact us to find out if Intellijoint KNEE has received regulatory clearance in your region.